Secondary process is aim for part surface decoration or protection, which will greatly improve the product Appearance or durability in extreme environments. We offer multiple surface finishing and secondary process options to complete the plastic products made with the plastic injection molding process. You can choose from any of the following depending upon your application’s requirements:

● Standard Finish: Interior, non-cosmetic finish according to the geometry of the mold.

● SPI Finishes: Range of SPI finishes from Grade 3 diamond / high polish to 320 stone low polish.

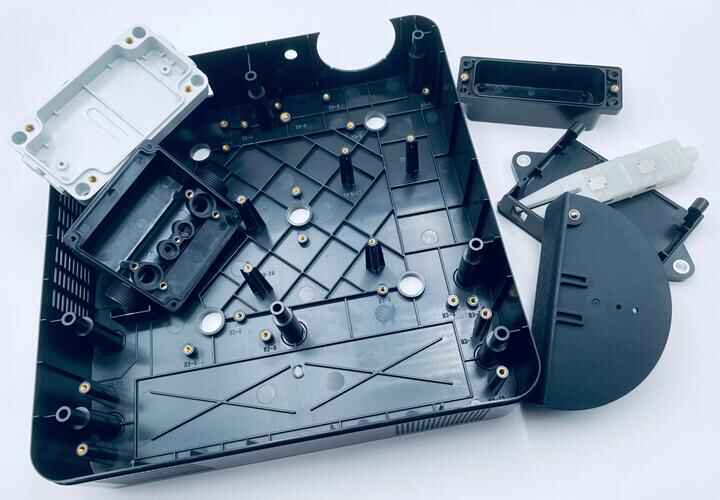

● Threaded Inserts: We can install the most commonly used and popular standard inserts in UNF and metric sizes.

● Mold Texturing: Creating textures on the molds so that it shows on the final product.This finishing option includes matte, swirls, patterns, and lines.

● Laser Engraving: Engrave part numbers, designs, logos, or any other specified printing onto your parts.

● Pad Printing: Application of an ink-based design to the surface.

● Silk Painting: Painting the surface with standard colors or Pantone matching, including Primer and topcoat, Masking available, EMI (copper) paint.