Injection Molding

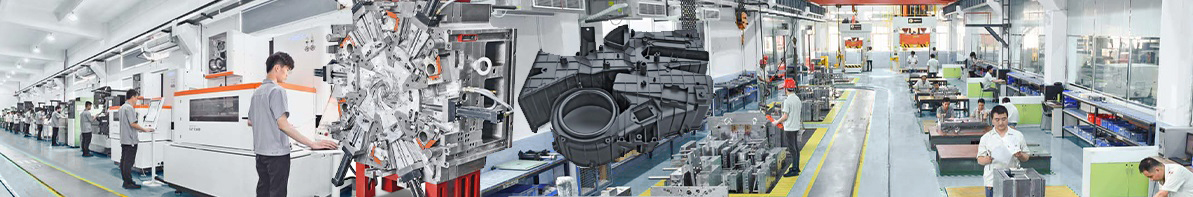

MJX Mold is a full-service plastic injection molding manufacturer in custom manufacturing. With our experienced tool makers and setters, we can achieve optimal product output in a minimal amount of time. We mold your products to meet your specifications and put them through our quality inspection department to guarantee accuracy and quality at all times. ● 1 Clean Room Molding (100K class) with 50 electric molding machines; ISO 9001:2015, ISO 14001:2015 certified ● 100+ Injection Machines (Range from 50-1300T, electric x24, vertical 1x, two shot x3), we can achieve optimal product output in a minimal amount of time. ● On-site injection plastic mold repair & maintenance ● Insert molding, dual-color molding service ● Tight Tolerance and Quality Controls ● Injection and SF molding with gas counter pressure capabilities. Value-added services ☆ Laser Finishing ☆ Bead Blasting ☆ In-Mold Decoration ☆ Pad Printing ☆ Silk printing ☆ Electroplating

Injection Molding Techniques

Clean Room Molding

Clean Room Molding

In clean room molding, plastic parts are made in a special room designed to prevent contamination by dust or other particles. In industries such as medicine, pharmaceuticals, aerospace, and defense, parts are frequently made in clean rooms.

High Temperature Molding

High Temperature Molding

PEEK (Victrex), PPA (Amodel), PAI (Torlon), PPS (Ryton, Fortron), PPSU (Solvay), PEI (Ultem) and a number of other engineered grades are some of the commonly used high-temperature resins. We at MJX Mold work with high-temperature resin materials and can obtain the resins in a variety of colors.

Overmolding

Overmolding

Utilized to combine several materials seamlessly, over molding is an injection molding technique where a second layer of molding resin covers the previous layer. The result is a solid bond between layers that add multiple resistances to the completed product and a durable and smooth finish.

Insert Molding

Insert Molding

A variation of the traditional injection molding process, insert molding is a technique where a metal part is placed into a mold before the actual injection molding. Insert molding makes assembly of multiple parts faster and easier while reducing costs and production time.