Prototyping and 3D printing

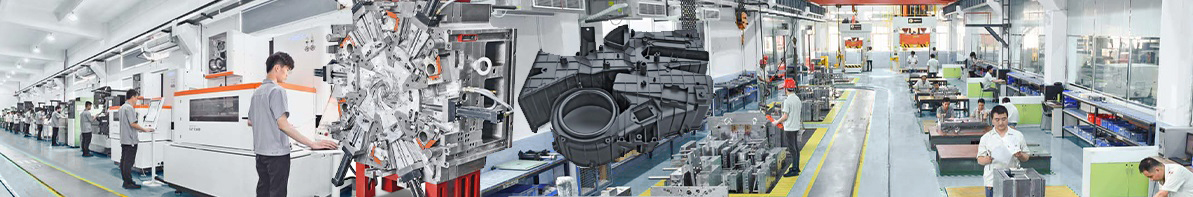

Prototyping and 3D printing are integral to the plastic mold industry, offering significant advantages in design verification, cost reduction, and time-to-market acceleration. Prototyping allows for the testing and refinement of product designs before committing to expensive mold manufacturing, ensuring that the final product meets all specifications and market demands. MJX MOLD specialized in precision plastic injection molds and parts, from prototypes to mass production offering advanced technology and extensive industry experience.

Technologies and Materials:

Prototyping is a critical stage of product development that allows designers and engineers to validate, test, and improve their design concepts. 3D printing, CNC machining, and Vacuum Casting are three commonly used prototyping techniques that each have their own characteristics in terms of the appearance, structure, and function of producing prototypes.

Materials include plastics (ABS, PLA, PETG, PC), metals (aluminum, steel), rubber/silicone, and resins. The selection of technology and materials for prototyping is driven by its intended use, complexity, and durability. The objective is to mirror the final product’s functionality and aesthetics, while managing cost and time effectively.

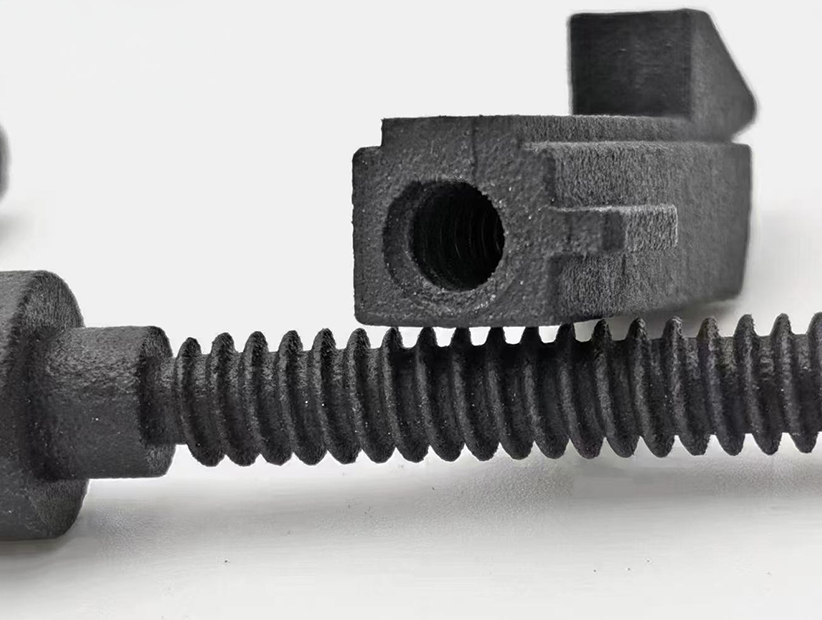

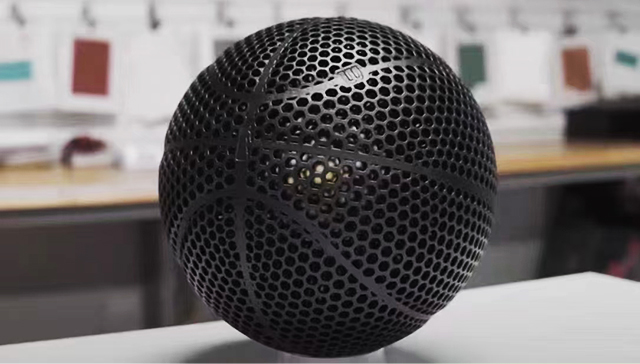

3D Printing: SLA, SLS, FDM, DLP for accurate and quick models.

3D Printing: SLA, SLS, FDM, DLP for accurate and quick models.

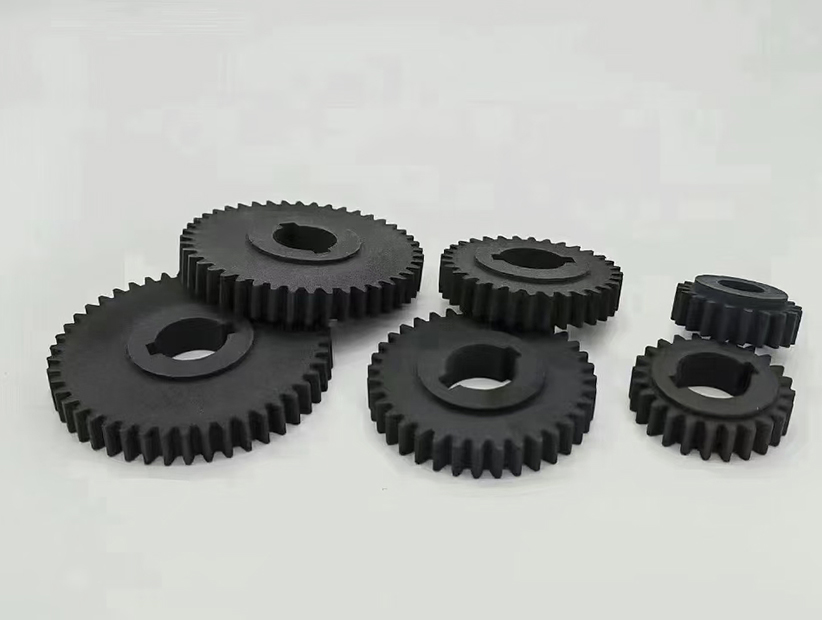

CNC Machining: Precision cutting for robust prototypes.

CNC Machining: Precision cutting for robust prototypes.

Vacuum Casting:Silicone mold-making for small batch parts.

Vacuum Casting:Silicone mold-making for small batch parts.