Automotive

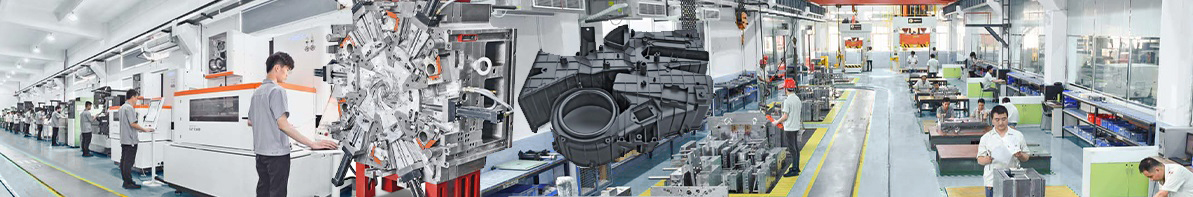

MJX MOLD has extensive experience in designing and injection molding for Automotive Exterior and Interior Parts. We are aiming to make car interiors plastic parts luxurious, appealing, and more comfortable. We also apply them as exterior components in headlights, bumpers, and other parts because high-quality plastic is durable and weather-resistant.

Our staff is well-trained in specialized techniques like insert molding and over-molding which are essential in manufacturing plastic car parts with a strong durable structure. We also use premium plastic materials and cutting-edge technology to produce each part with flawless precision. We are injection molding designers and manufacturers for several leading automobile brands such as BMW, Porsche, Mercedes, Tesla and so on.

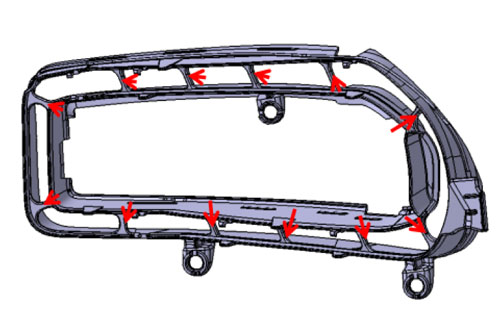

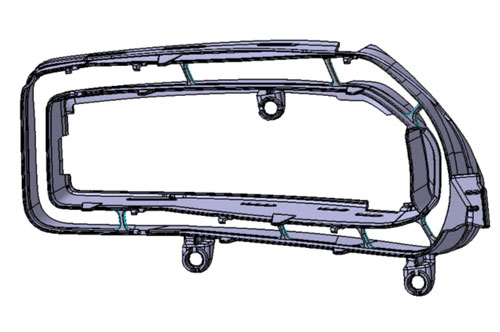

Successful Case Automotive Light Housing

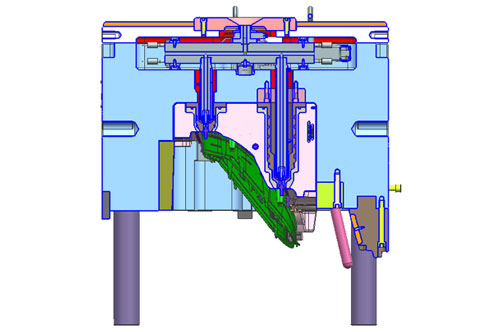

Complete program in 8 weeks including design and adjustments after T1. Program shipped to Germany for production after Trial 2. Our recommendations resulted in elimination of distortion during ejection and reduced cycle time.

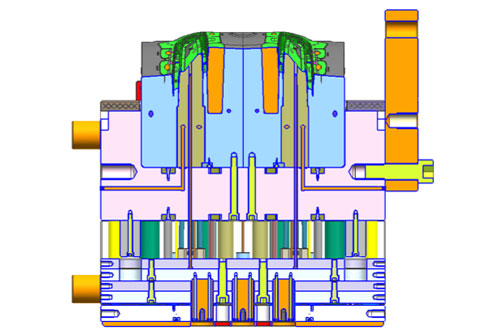

Project Name | Holding Frame LH/RH |

No. of Cavity | 1+1 |

Steel | Groditz Stee for Core(1.2343 HRC 48-50) ; Cavity 1.2343 HRC 50-52) |

Injection System | Mold Masters Hot Runner Manifold 4 Hot Drops into Cold Runner Sub-gate |

Resin | PC/ABS (INFINO WP1089/Black) |

Shrinkage Rate | 1.0055 (0.55%) |

Surface Finishing | Cavity (SPI-A1 High Gross Polished); Core (SPI-B2) |

Tooling Size & Weight | 1005.7*947.65*700 mm; 3500KG |

Part Weight | 130g |

Press Ton | 750 Ton |

| ||

| Add Stripper Bars to avoid deformation Eliminated Distortion | ||

|

|

|

| 1 + 1 Cavity | Groditz Steel for Core and Cavity | SPI-A1 High Gloss Polish |

Note: The parts get easily deformed during ejection.