DFM & Mold Design

MJX Mold provide engineering guidance to help you design moldable parts optimized for manufacture after Project Review. From tool design concepts to process development and validation, we ensure that all aspects of production meet the ultimate goal of producing high-quality injection molded parts. Aiming to providing the most efficency mold solution to meet our customers molding production demand, through DFM(Design for Manufacturing) process, we help our customer to optimize their part design to achieve cost wise manufacturing and make the prefect injection molded parts by:

● Wall Thickness Analysis

● Draft Angle, Assembly Review

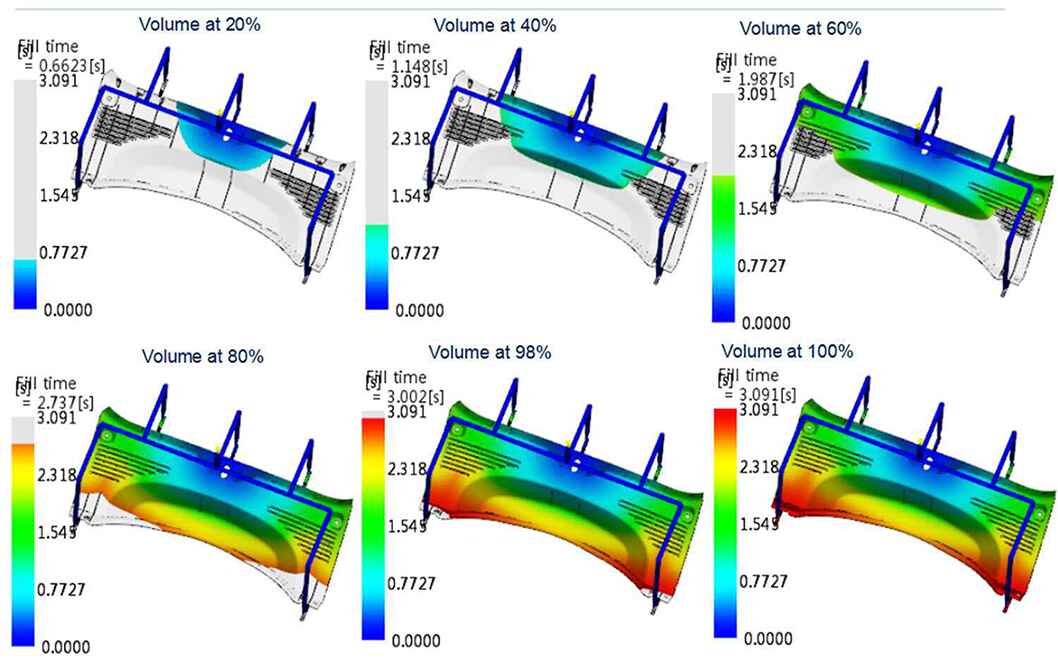

● Mold Flow Analysis

● Injection Mold accessories and Standard

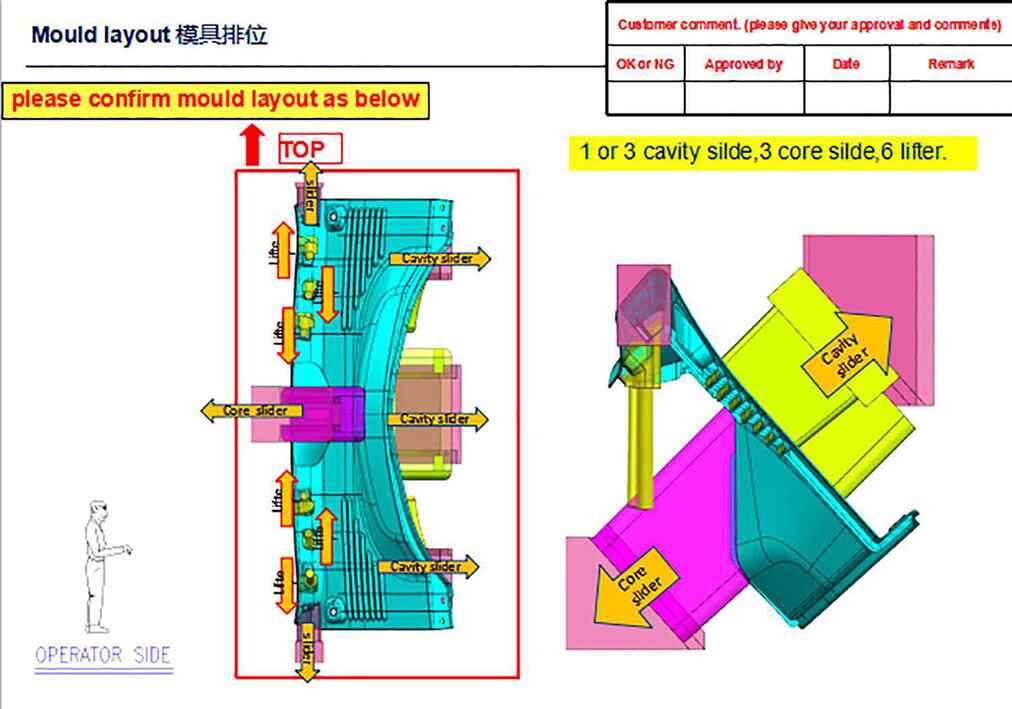

● Mold Layout and Cavitation

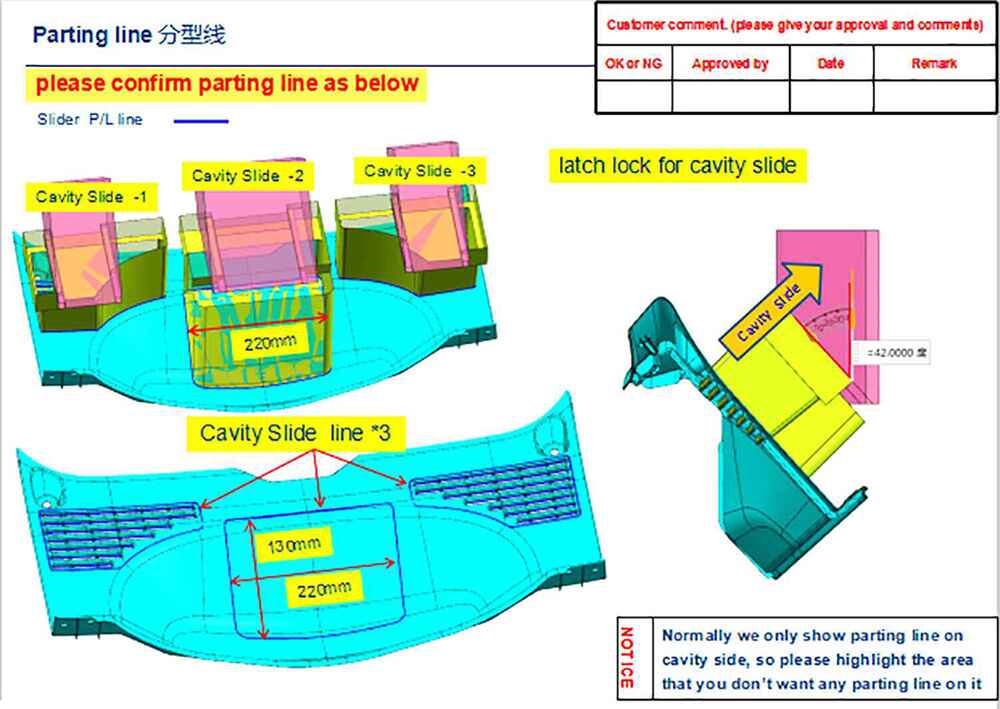

● Plastic Injection Mold Design: Parting Line, Shrinkage, Runner System/Gating ways, Cooling Layout, Ejection, Demolding, etc

We can support you in development of your new projects or re-design current products and implement these steps on behalf of clients by meeting in person and teleconferencing with you and your sales & marketing and technical people each step of the way. We use UG for 3D mold design and NC programming, Auto CAD for 2D drawings, accept files in format X-T, Step, IGES, Stl, Prt, SLDPrt, Dwg, Dxf, and PDF.

Product Development | Mold Design Support | Engineering Software | ||

| | | ||

| | | ||

| | | ||

| | | ||

| | |

Mold Designs That Help You Increase Profit

MJX Mold is specialized in mold design process and plays a signicant role in providing you with tailor-made, cost-effective, and short lead time to market for automated processing, eliminating unnecessary costs while increasing productivity.molding solutions. Our intuitive mold designs are intended for automated processing, eliminating unnecessary costs while increasing productivity.

Enhance Profitability |

Boost Productivity |

Low Maintence | ||

With faster production time and reliable mold designs, you can fulfill more customer orders and improve profit margins. | Automated production reduces defective or unsatisfactory parts, resulting in higher product output with consistent quality. | MJX mold are made for easy assembly and disassembly, low risk of wore-out,easy for replacement. |

Early-Stage Engineering Support

Early-Stage Engineering Support Mold drawing 2D & 3D

Mold drawing 2D & 3D

Quality Requirement Planning

Quality Requirement Planning Design for Manufacturable

Design for Manufacturable CAD

CAD Material Selection Consultation

Material Selection Consultation Mold Design Checked

Mold Design Checked MoldFlow

MoldFlow Mold Concept Planning

Mold Concept Planning Mold Design Specification

Mold Design Specification STEP

STEP  Part Optimizing

Part Optimizing Mold Design Optimized

Mold Design Optimized SOLIDWORKS

SOLIDWORKS