Bi-Color (2K & Overmolding)

2K injection molding, also known as two-shot injection molding, is a revolutionary process in the realm of plastic component manufacturing. This advanced technique enables the production of complex, multi-material components through a single, automated process.

If you’re interested in 2K injection molding, you might want to consider our expertise in multi-shot injection molding and plastic two-shot injection molding. With these processes, we can efficiently and economically mold parts using two or more plastic resins or colors in one operation. Our team has extensive experience in designing and manufacturing high-quality molds for a wide variety of multi-shot and two-shot injection molded plastics.

The benefits of Double Injection molding are numerous and significant. This cutting-edge manufacturing process has revolutionized the way plastic parts are made, providing a range of advantages that include cost savings, improved product quality, and more.

One of the key advantages of Double Injection is its ability to lower unit costs. By combining two different materials in a single mold, manufacturers can eliminate the need for costly assembly processes, reducing labor costs and saving time Manufacturers can create parts that feature multiple materials, colors, and textures, all in one single mold. This saves time and reduces waste, while also providing greater design flexibility and more customization options for customers.Double Injection also reduces the need for secondary assembly and handling, which can help to further lower costs and improve efficiency.

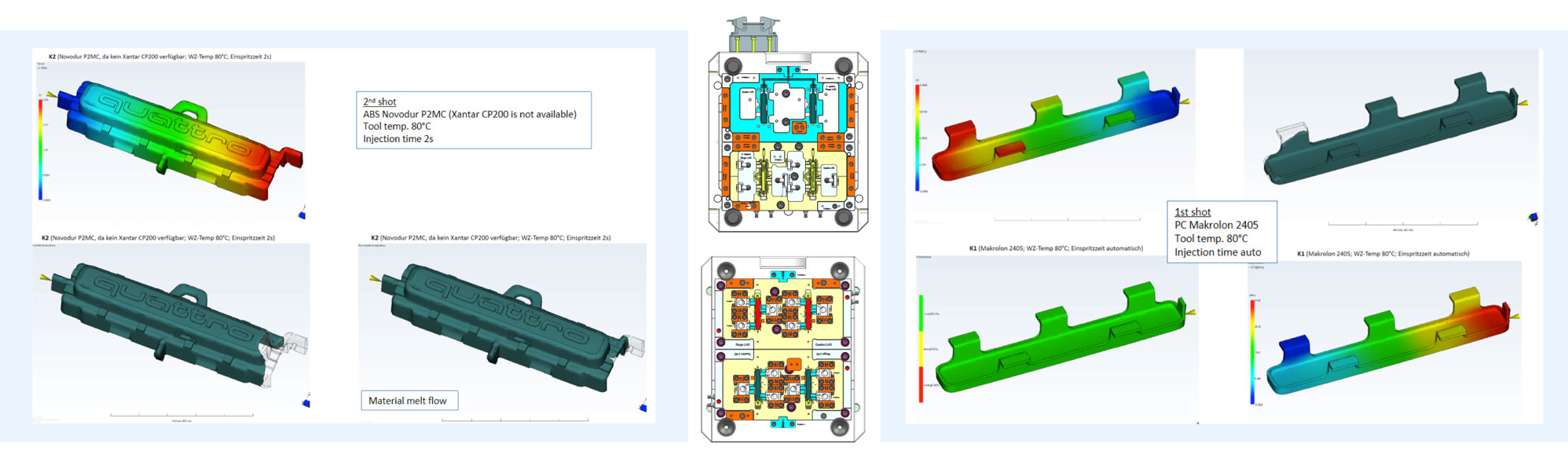

2 Shots Rotational Injection Mold Case

Part name : | Car Brand Lamp |

No. of Cavity : | 1+1; (2K Rotational Injection Mold) |

Steel for Cavity & Core : | Groeditz Steel 1.2343ESR , HRC50-52 |

Injection System : | INCOE Hot Runner Connector Configuration |

Resin: | ABS/PC & PC |

Shrinkage Rate : | 0.55% |

Surface Finish : | A-Surface (visible/cosmetic part) 1000 grit; B/C-Surface (partially visible or invisible part areas) 600 grit |

Tool Size & Weight : | 396 X 446 X 375mm; 400KG |

Part Weight : | 8g |

Press Ton : | 110 Ton |