News

Services of Mold Flow Analysis

|

Mold flow analysis simulates the flow process of plastic melt within the mold cavity, generating detailed color charts that illustrate the anticipated outcomes. This technology encompasses multiple parameters, including the heating and cooling of the material, injection filling patterns, injection dynamics, shear stress distribution, and various other pivotal elements.

Mold flow analysis simulates the flow process of plastic melt within the mold cavity, generating detailed color charts that illustrate the anticipated outcomes. This technology encompasses multiple parameters, including the heating and cooling of the material, injection filling patterns, injection dynamics, shear stress distribution, and various other pivotal elements.

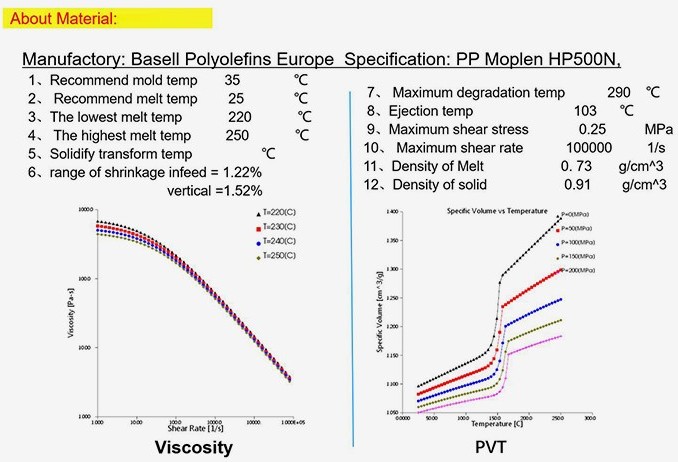

Plastic Material

Plastic Material

Choose plastic materials that fulfill the product performance specifications and facilitate ease of processing, taking into account the material's flow characteristics, shrinkage ratio, thermal stability, and chemical compatibility.

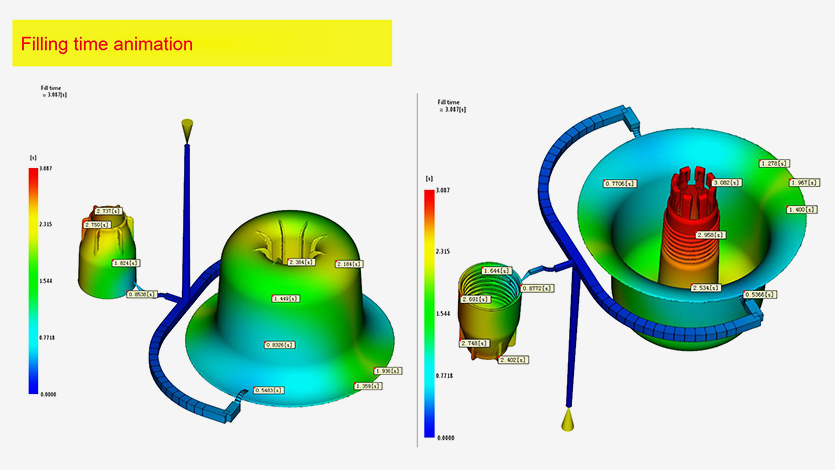

Filling Animation

Filling Animation

This analysis focuses on studying the flow behavior of molten plastic within the mold cavity to predict potential injection molding defects such as short shots, incomplete filling, warpage, weld lines, and air traps. Through precise simulation of the filling process, the aim is to identify and address potential production issues in advance, ensuring the quality and performance of the final product.

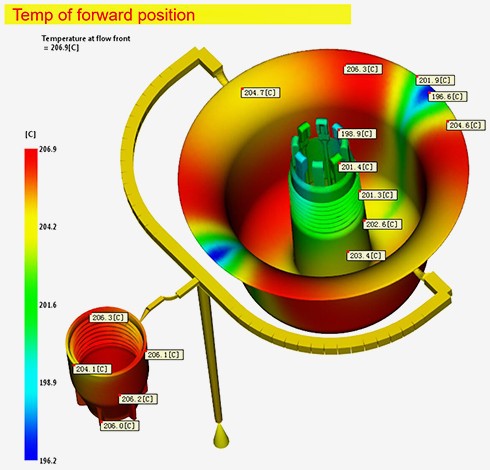

Temperature Distribution

Temperature Distribution

An excessively high mold temperature can lead to adequate cooling of the product, potentially leading to extended cycle times and dimensional instability. Conversely, a mold temperature that is too low may cause product warping and stress-related defects. Adjusting the mold temperature settings and melt temperature is essential to optimize the temperature distribution, thereby improving the product's appearance and performance.

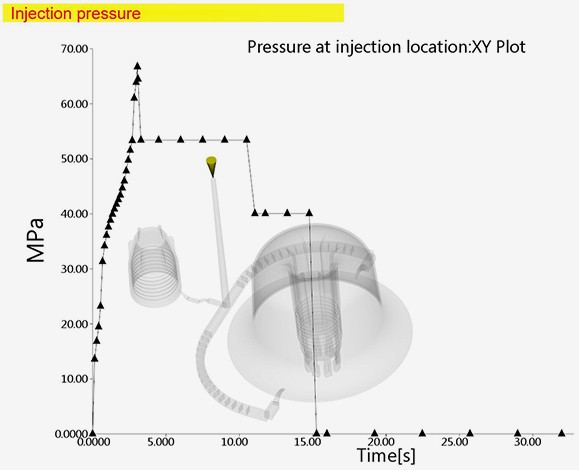

Pressure Distribution

Pressure Distribution

An imbalance in injection pressure, whether excessively high or deficient, can result in product fracturing, defects, or incomplete cavity filling. The optimization of injection speed and pressure is crucial for achieving an equitable pressure distribution within the mold, thereby preventing stress concentrations and product deformation.

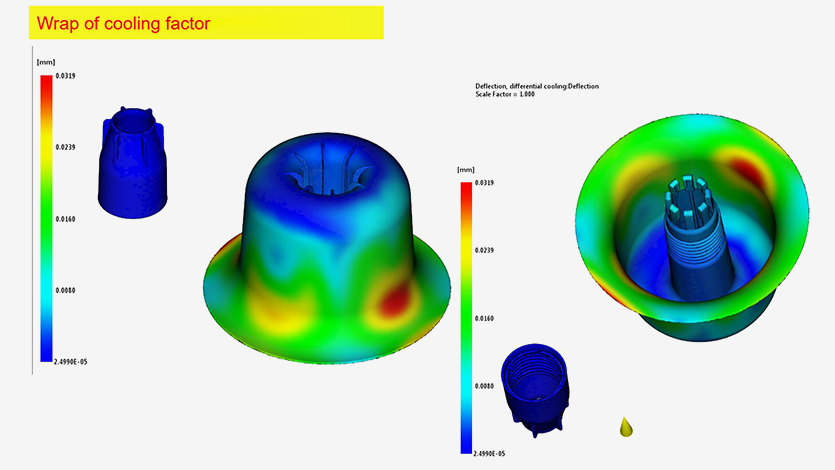

Cooling Analysis

Cooling Analysis

Perform a cooling analysis to simulate the flow of cooling water within the mold and the process of heat exchange. Observe and analyze the performance of the cooling system, including changes in the temperature of the cooling water, the distribution of mold temperatures, and the cooling rate of the product. Evaluate the design of the mold's cooling system to ensure uniform cooling and to reduce product deformation and stress.

Contact:

Company : Shenzhen MJX Plastic Mold Co.,Ltd

Website: : www.mjxmold.com

Email : sales@mjxmold.com

Phone : +(86) 134 2182 9809 (WhatsApp)

Address : Block 11, Area B, Xianan Industrial Zone, Shangcun Community, Gongming Street, Guangming District, Shenzhen, Guangdong Province, China